ENERGY MANAGEMENT

MARPOL ANNEX VI REGULATION 22 FOR SEEMP

Ship Energy Efficiency Management Plan (SEEMP)

Each ship shall keep on board a ship specific Ship Energy Efficiency Management Plan (SEEMP).

This may form part of the ship's Safety Management System (SMS).

The SEEMP is developed taking into account guidelines adopted by the Organization.

All vessels are supplied with EEOI Software and License key

Carbon di Oxide causes the Greenhouse effect and is believed to be responsible for the global warming.

The average concentration is now 412 ppm as compared to 280 ppm prior industrialization which is an increase of 47%.

The carbon dioxide once emitted to atmosphere, remains for an average of 200 -300 years.

Hence, the carbon dioxide concentration is increasing rapidly due to the burning of fossil fuels.

Carbon di Oxide causes the Greenhouse

The average concentration is now 412 ppm

The carbon dioxide once emitted to

Hence, the carbon dioxide

HOW CAN WE REDUCE CO2 EMISSIONS - MANAGE ENERGY

By way of our Routine Planning for a Voyage - Voyage Planning

-Just in Time Arrival

-Optimized Speed

-Optimum Ballast

-Optimum Trim

-Tuning of Auto Pilot settings

B

-

-

-

-

-

HOW CAN WE REDUCE CO2 EMISSIONS - MANAGE ENERGY

Manage by way of Installing Optimized Units or System Upgrades

- Retrofit of New Optimized Propeller & Propeller Boss Cap Fin

- Retrofit of New Optimized Bow

- Retrofit of New Exhaust gas boilers for specific Auxiliary Engines to run in Port and minimize Aux Boiler use.

- Retrofit of Fuel Nozzles with Sacless type (called Slide type on MAN B&W and FAST nozzles on Wartsila)

- Retrofit of ‘Auto – PMI – VIT’ for MAN B&W Engines OR ‘Injection Timing Automation’ for Wartsila RTA Engines

- Retrofit of New Variable Frequency Drives for ER Blowers, Cargo Hold Blowers, SW Pumps etc.

Manage by way of Monitoring Performance

- Regular Monitoring of Slip, carrying out necessary Inspection & Cleaning of Hull and Propeller.

- Regular Monitoring of Engine Parameters and SFOC and carry out necessary Cleaning of Charge air Cooler, Exhaust gas Economizer, Turbocharger Suction filter, T/C Grid, Heat Exchangers etc.

- Monitor Boiler running for Steam consumption and check if steam is open for unnecessary consumers OR any new insulation required etc.

- Regular Maintenance of Machinery

- Etc..

REGULATORY AUTHORITIES NOW NEED FUEL CONSUMPTION – IMO DCS & EU MRV

Data Collection System (DCS) for the IMO is mandatory and the first step in a larger process to collect and analyze shipping emissions data.

This is also called SEEMP PART II.

The Owners / Managers are responsible to collect and report data from the date of take over.

The Monitoring, Reporting and Verification (MRV) system for the EU and UK is important to collect and process the emissions in EU / UK Trading area.

If the vessel has been taken over in the middle of the year by the owners, then it is still the responsibility of the Present owners / managers to collect the data for the whole year and report EU / UK related voyages

This is also called

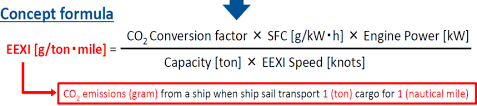

EEXI – ENERGY EFFICIENCY DESIGN INDEX FOR EXISTING SHIPS

The IMO Energy Efficiency Design Index for existing ships (EEXI), requires a vessel to achieve a required level of technical efficiency (required EEXI) under specified reference conditions, is a new measure to support the IMO Strategy on reduction of GHG emissions from ships.

Attained EEXI should be calculated for ships above 400 GT.

The Attained EEXI should be less than or Equal to Required EEXI.

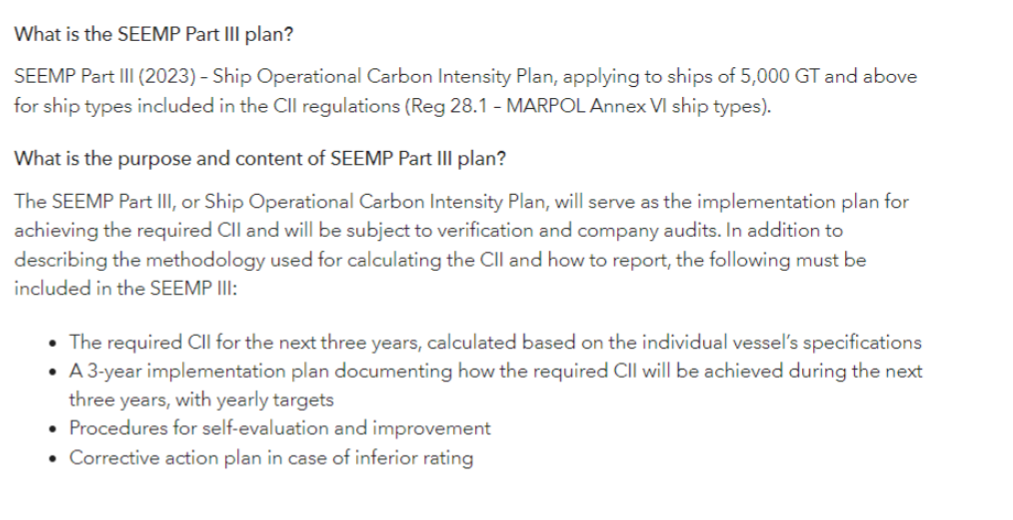

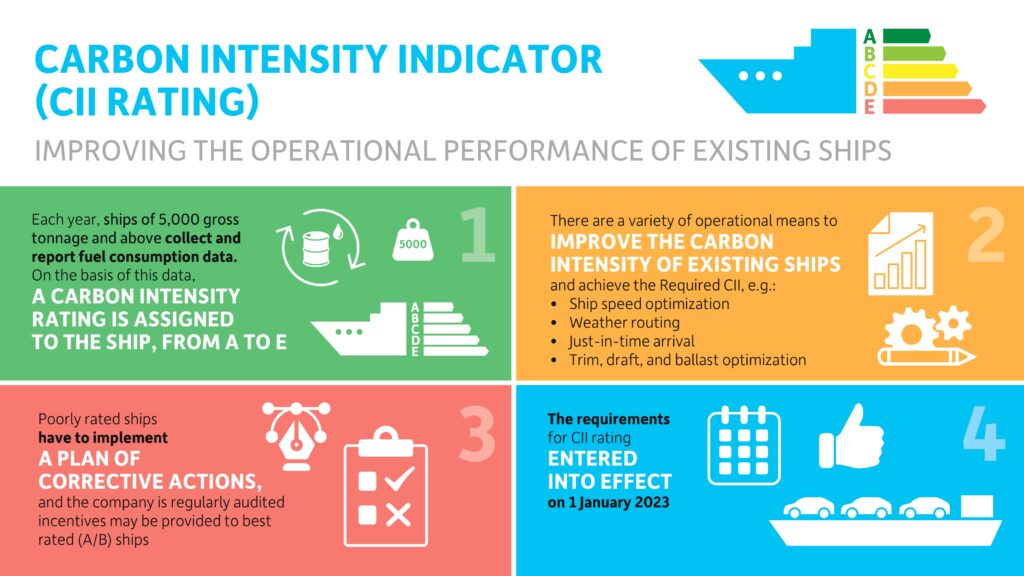

SEEMP PART III – CII (CARBON INTENSITY INDEX)

WORLD PORTS SUSTAINABILITY PROGRAM & ESI

What is the Environmental Ship Index (ESI)?

The Environmental Ship Index (ESI) identifies seagoing ships that perform better in reducing air emissions than required by the current emission standards of the International Maritime Organization, the Environmental Ship Index.

The ESI evaluates the amount of Carbon di oxide (CO2), Nitrogen oxide (NOX), Sulphur oxide (SOX) that is released by a ship and includes a reporting scheme on the greenhouse gas emission of the ship.

ESI has become the standard tool used by the world’s ports to reward and incentivize shipowners meeting and exceeding IMO emissions standards.

What is required from vessel for reporting to WPSP to calculate Environmental Ship Index (ESI)?

1.Latest IAPP Certificate (International Air Pollution Prevention)

2. EIAPP Certificates (Engine International Air Pollution Prevention) For all the engines Main engine and Auxiliary Engines. Consider that we need all pages to clarify various information.

3. Refueling reports to be completely reported in VRS software for automatic collection of BDN data.

4. Scrubber Vessels to make sure that SO2/CO2 is successfully reported in VRS when scrubber is on.

5. Clarify if your Vessel has Cold Ironing (Onshore Power System) and while in Commercial use at port stay it can draw power from Shore connection.

1.